Potentiometer Linearity Study | April 2019

“A chain is no stronger than its weakest link.”

This is especially true within the scientific environment that is the knock engine lab. Every effort is made to improve the quality of results that are reported by a respective lab. All the training and maintenance procedures that have been implemented and completed may only achieve a certain level of accuracy. The accuracy lost is beyond the control of the user because the equipment is limiting them at critical points of the octane rating procedure.

During our time servicing and refurbishing 501-C detonation meters, we discovered that the fine-tuning potentiometers for meter and spread were both lacking the linearity required to reliably calibrate them and provide the stability that was acceptable by our quality standards.

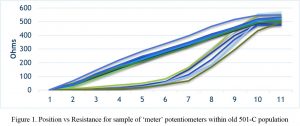

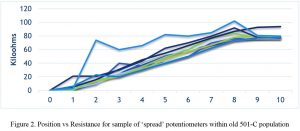

To discover the malfunctioning pieces before installing them in refurbished units, we developed a process to chart the internal resistance of the potentiometers throughout their range and plotted them with respect to the position the potentiometer is turned to. Figures 1 and 2, respectively, show this relationship for both the meter and spread potentiometers.

It is evident by Figures 1 and 2 that there is a subset of the 501-C population that have different potentiometers within them. But what does this mean for the testing environment? Within D2699 and D2700, the test method calls for maximizing the spread on the analog knockmeter.

In D2700, “Standard Test Method for Motor Octane Number of Spark-Ignition Engine Fuel”, section 14.3.3 states:

“14.3.3 When using the analog knockmeter, check that detonation

meter spread is maximized commensurate with satisfactory

knockmeter stability. (No adjustment of the digital detonation

meter is necessary.)”

The methods require precise adjustments of the spread dials of the analog meter. Figures 1 and 2 show that there can be significant differences between potentiometers and if a precise adjustment is not possible, the accuracy of the overall test may be somewhat limited if knockmeter stability cannot be achieved with low quality components.

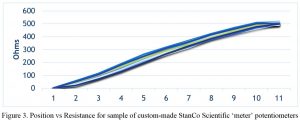

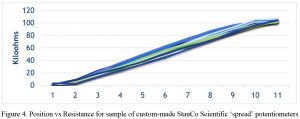

To achieve better levels of stability, StanCo Scientific sourced high quality, custom-made, potentiometers to use in the refurbished 501-C detonation meters that pass through our service center. Figures 3 and 4 illustrate the improved linearity of these potentiometers.

With these new potentiometers sourced and installed, several benefits have been added to the refurbishment process:

- Faster overall productivity

- More reliable calibration profiles

- Smaller standard deviation throughout the 501-C population

We’ve been able to provide faster turnaround times with the addition of standardized potentiometers. These new pieces have resulted in tighter tolerances that provide more reliable operation and uniformity between all refurbished 501-C meters that have been refurbished by StanCo Scientific.

Our goal is always to provide longevity within the testing industry while also improving it when ways are found to do that efficiently and cost effectively. New phenomena are discovered all the time and improvements are slowly being made to provide the best equipment possible.